Product range

Air compressor desiccant dryers BD+ CD+ XD+

BD+ series 100-3000 l/s

CD+ series 25-1400 l/s

XD+ series 550-3600 l/s

Energy-efficient compressed air dryer systems. Ideal for high air demands, constant use and critical processes. With advanced monitoring and control.

BD+ and CD+ are designed to work with oil-lubricated and oil-free air compressors. XD+ is designed to specifically work with oil-free air compressors.

- Description

- Benefits

- Downloads

- Related products

- Services Contact us

Description

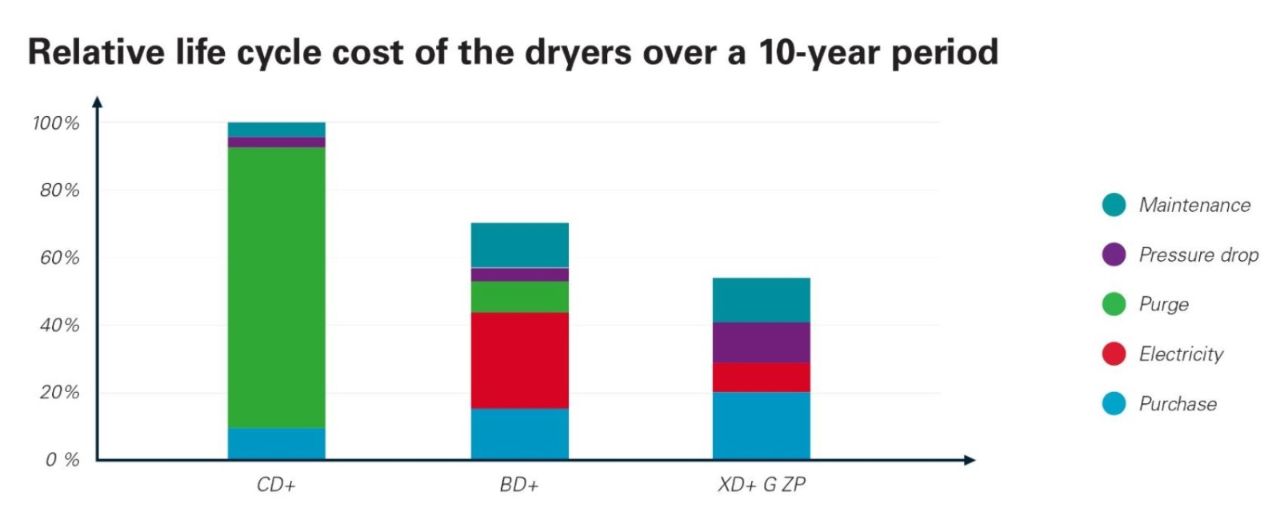

Desiccant type of dryers BD+, CD+ and XD+ compared

BD+ heated blower purge desiccant air dryers use a combination of heated air from an external blower, and only a minimal amount of compressed air. BD+ desiccant air dryers are also available in a zero purge variant.

CD+ heatless desiccant air dryers are the simplest and only use only compressed air as a purge, minimizing electrical connections.

XD+ with zero purge cooling uses the heat of compression recovered from the compressor for the regeneration of the desiccant. The XD+ dryer does not consume any compressed air during the heating or cooling process.

By eliminating moisture, you can increase your production equipment’s reliability and improve the quality of your finished goods with dried compressed air.

All air dryers incorporate unique, patented technology and energy-saving options.

Available in a range of sizes with a pressure dewpoint as low as -70°C/-100°F.

Benefits

Benefits

Downloads

Digital brochure BD+ CD+ XD+