The Atlas Copco XAS 1800 CD is a single-stage, oil-injected, rotary screw type air compressor, powered by a liquid-cooled, 6 cylinder turbocharged diesel engine.

The unit consists of two parallel low pressure air ends, diesel engine with exhaust treatment, cooling circuit, air/oil separation and control systems - all within a sound dampened steel enclosure.

A range of factory and locally installed options are available.

Special attention has been given to the overall product quality, user friendliness, ease of serviceability, and economical operation to ensure best in class cost of ownership.

• Main Screen 1

- Vessel Pressure

- Fuel & DEF Level

- Running Hours

- RPM

• Main Screen 2

- Vessel Pressure

- Fuel & DEF Level

- Running Hours

- RPM

- Element Temp

- Regulating Pressure

- Battery Voltage

• General Settings

- Engine Diagnostics

- Auto Start/Load/Stop

- 30 Languages

- Units of Measure

- Auto diagnostic function for the engine

• Alarms

- Structured alarms can be added to alert in

advance to take proactive action

- Active Alarms

- Event Log History

- Alarm Log History

• Measurements

- Fuel Consumption

- Engine Coolant Temperature

- Compressor Element Temperature

- Vessel Pressure

- Air Discharge Pressure

- Inlet Pressure

- Ambient Temperature

- Aftercooler Air Temperature

- E-Stop count

- Oil Stop Valve Pressure

- Engine Load

- Engine Oil Pressure

- Engine Boost Pressure

- DPF Soot Load

- Fuel Temperature

- Battery Voltage

- Regulatory Pressure

- Loaded/Unloaded Hours

- Successful/Unsuccessful Starts

- Service Timers (2 resettable)

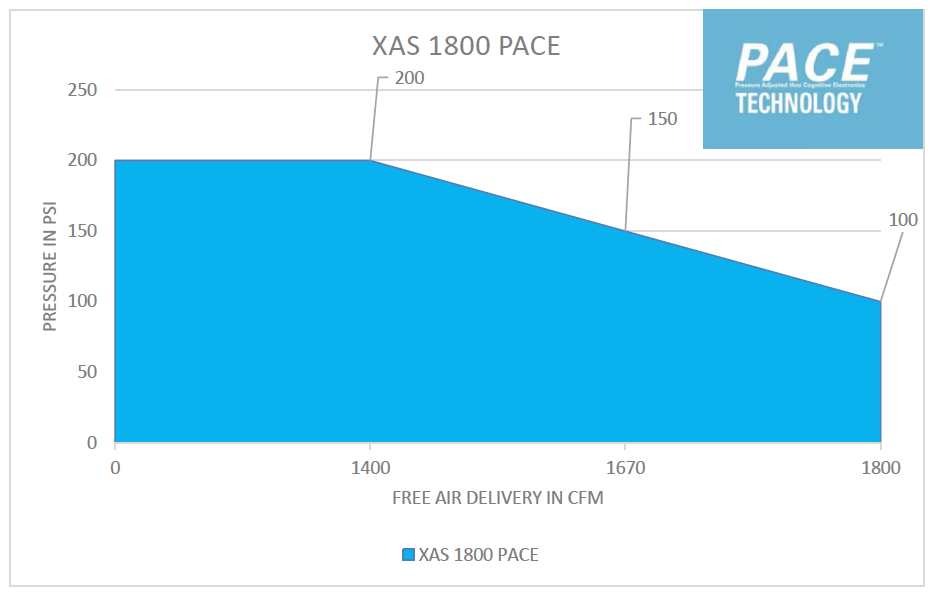

| Normal effective working pressure (pre-set 200 psig and 150 psig) | Psi | 100 | 150 | 200 |

| Actual free air delivery (FAD) at pre-set pressure setting | Cfm | 1811 | 1669 | 1403 |

| Maximum effective receiver pressure (compressor unloaded) | Psi | 261 | 261 | 261 |

| Minimum / Maximum working pressure | Psi | 72.5 / 200 | 72.5 / 200 | 72.5 / 200 |

| Max. sound pressure level @ 23’ (7m) at normal working speed & pressure | dB(a) | 76 | 76 | 76 |

| Compression Stages | 1 | 1 | 1 | |

| Air Receiver Capacity | US Gal (L) | 37.8 (143) | 37.8 (143) | 37.8 (143) |

| Compressor oil capacity | US Gal (L) | 30 (113.6) | 30 (113.6) | 30 (113.6) |

| Approximate air outlet temperature (without / with aftercooler) | °F (°C) | 180 (82) / 100 (38) | 180 (82) / 100 (38) | 180 (82) / 100 (38) |

| Air Compressor outlets | 2 x 2“ NPT (1 x normal air, 1 x after-cooled air) | 2 x 2“ NPT (1 x normal air, 1 x after-cooled air)” | 2 x 2“ NPT (1 x normal air, 1 x after-cooled air) | |

| Max. ambient temperature (at sea level) | °F (°C) | 125 (50) | 125 (50) | 125 (50) |

| Maximum altitude | Ft (m) | 8200 (2500) | 8200 (2500) | 8200 (2500) |

| Minimum starting temperature | °F (°C) | 14 (-10) | 14 (-10) | 14 (-10) |

| Minimum starting temperature (with cold weather options) | °F (°C) | TBD | TBD | TBD |

| Engine | Caterpillar | C13 | ||

| Emissions Regulation | US EPA Tier | T4F | ||

| Output at rated speed (2100 rpm) | HP | 525 | ||

| Number of cylinders | 6 | |||

| Aspiration | Turbocharged | |||

| Displacement | cu in (L) | 762.8 (12.5) | ||

| Engine speed (Unloaded) | rpm | 1305 | ||

| Engine speed (Maximum loaded) | rpm | 2100 | 1980 | 1670 |

| Engine oil capacity | US Gal (L) | 11.97 (45.3) | ||

| Engine oil required | Low Ash Oil per API CJ-4, ACEA C9 | |||

| Engine coolant capacity | US Gal (L) | 22.75 (92) | ||

| Fuel tank capacity | US Gal (L) | 223 (844) | ||

| Fuel consumption at 0% loaded idle | Gal/Hr (L/Hr) | 4.4 (16.6) | 4.4 (16.6) | 4.4 (16.6) |

| Fuel consumption at 25% load | Gal/Hr (L/Hr) | 9.5 (35.8) | 11.5 (43.5) | 13.9 (52.6) |

| Fuel consumption at 50% load | Gal/Hr (L/Hr) | 10.8 (41) | 13.2 (50) | 14.6 (55.3) |

| Fuel consumption at 75% load | Gal/Hr (L/Hr) | 14.6 (54.9) | 15.2 (57.5) | 16.3 (61.7) |

| Fuel consumption at 100% load | Gal/Hr (L/Hr) | 22.7 (86.2) | 24.1 (90.9) | 21.7 (82.2) |

| DEF tank capacity | US Gal (L) | 18.5 (70) | ||

| DEF consumption at 100% load (100 psig operation) | Gal/Hr (L/Hr) | 1.7 (44.3) | ||

| Battery Capacity (Cold Cranking Amps) | A | 2 each 1400 |

In pipeline transportation, pigging takjes place when you're using pipeline inspection gauges, devices generally referred to as "pigs or scrapers", to perform various maintenance operations. Our large compressors are used to perform this mainteance without stopping the flow of the product in the pipeline.

Shotcrete, gunite, or sprayed concrete becomes an easier task when the materials are pushed through a hose and pneumatically projected at high velocity onto a surface using our air compressors. Whether you're doing road work, building a pool or laying concrete, our range of compressors can get the job done.

The larger compressor range provides one of the highest air volumes with low air pressure which is great for the drilling industry. This also makes these new compressors one of the most energy efficient by having a very low specific fuel consumption for the air delivered.