Why compressed air quality matters

In many cases, compressed air treatment is not only advisable but mandatory to maintain product quality. Having the right air quality will protect your company's reputation. Therefore it’s worth knowing which contaminants you may be exposed to, which compressed air quality standards you have to meet and what you can do to get there.

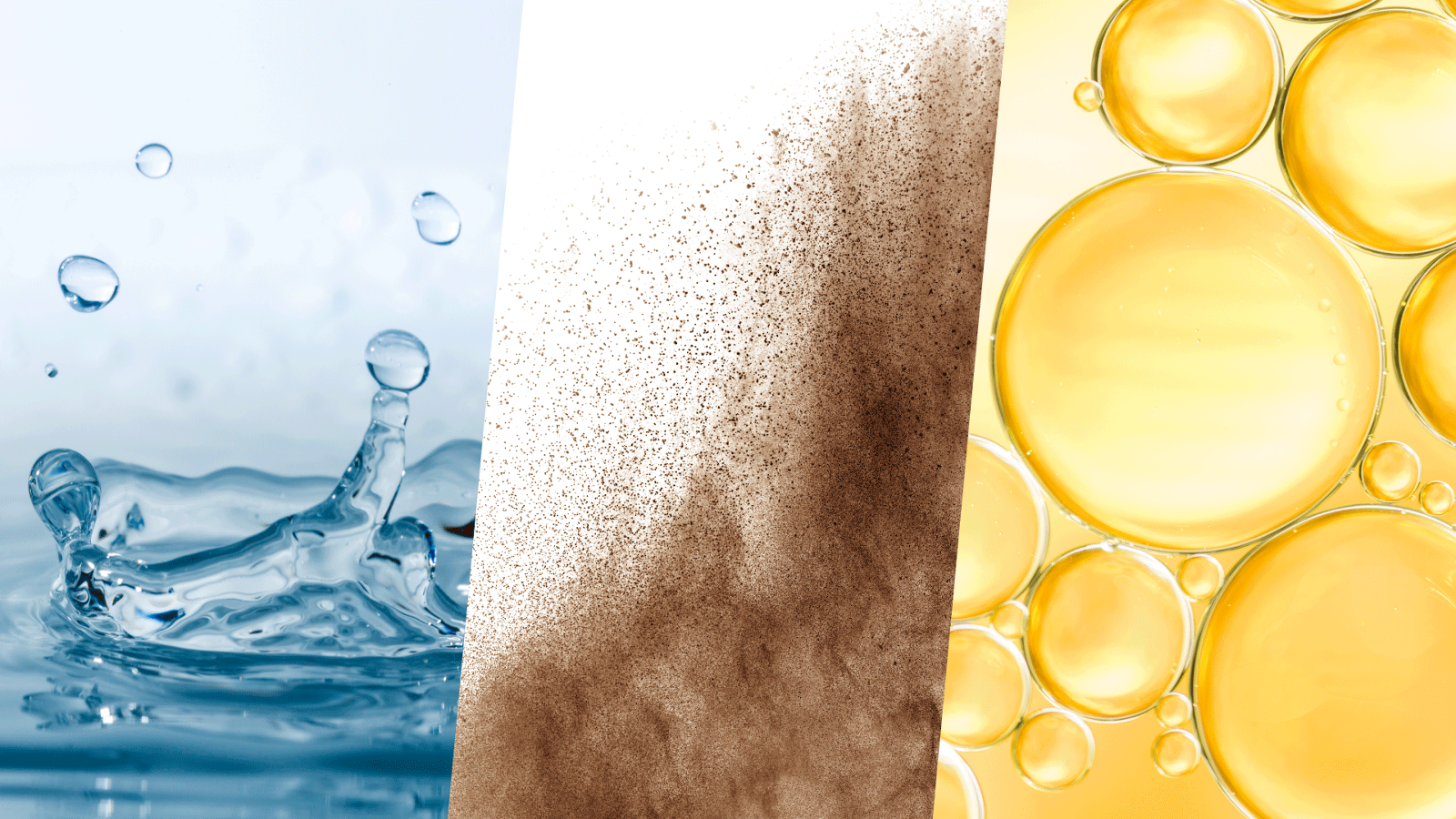

Ambient air isn't always clean enough for your production and can be a complex topic. Fortunately, there is something you can do about all types of compressed air contamination.

Depending on your application you will need to achieve a certain standard of compressed air quality to protect your equipment and end products. We can help you select the right equipment that is most suitable for your application.

Complying with the latest compressed air quality standards is crucial and doesn't have to be difficult. We have an overview of the different ways to test your air quality and even provide entire air audits for peace of mind.

If you need a steady supply of compressed air, understanding the importance of air quality and the different types of air treatment will help you along your journey.

After diving into the world of air treatment, you will soon realize why compressed air needs to be treated and which technologies are most suitable for your production process.

Our well designed compressed air systems, or as we call them - smart AIR solutions - can minimize your energy bills and keep them low in the future all while maintaining reliability and uptime of your production.