The Atlas Copco XAS 900 JD8 T4F is a single-stage, oil-injected, rotary screw type air compressor, powered by a liquid-cooled, six-cylinder turbocharged diesel engine.

The unit consists of an air end, diesel engine with exhaust treatment, cooling circuit, air/oil separation and control systems - all enclosed within a sound dampened powder coated galvanealed steel enclosure.

A range of undercarriage formats, factory and locally installed options are available. Special attention has been given to the overall product quality, user friendliness, ease of serviceability, and economical operation to ensure best in class cost of ownership.

Compact and maneuverable, saving valuable space on your job

Standard with 110% fluid containment and Tier 4 Final emissions the compressor is designed for use in all areas of the US and to meet stringent local site environmental concerns.

Atlas Copco’s FuelXpert™ seamlessly trims engine power under varying load conditions to reduce fuel consumption up to 15%.

2 layer protective coating (Primer base and Powder Coated top layer) steel enclosure with very large doors for superior access, makes maintenance easy.

Atlas Copco’s PFF system ensures cool, clean and dry air. The PFF system is plumbed through a secondary outlet so you can isolate the hoses and hardware requiring this purity of air. The PFF system comes standard with a three way valve the operator can select various air quality levels and optimal cold weather configuration.

| Model | XAS 900 JD8 | ||

| Actual free air delivery (Standard air) | CFM* | 750 | 867 |

| Actual free air delivery (Aftercooled air)** | CFM* | 720 | 837 |

| Working pressure | psi (Bar) | 150 | 100 |

| Working pressure range | psi (Bar) | -175 | |

| Engine | |||

| Model | John Deere | ||

| Displacement | L | ||

| Cylinders | # | ||

| Tier | US EPA | ||

| Exhaust after-treatment | |||

| HP | |||

| Rated speed (High) | RPM | ||

| Rated speed (Low) | RPM | ||

| Fuel tank capacity | Gal (L) | ||

| Fuel consumption @ 100% load | Gal/hr (L/hr) | 10.7(40.5) | 10.7(40.5) |

| Fuel autonomy @ 100% load | Hours | 8.2 | 8.2 |

| DEF tank capacity | Gal (L) | ||

| DEF autonomy @ 100% load*** | Hours | ||

HDD is a trenchless technology that use surface-launched equipment to drill underground horizontally and install pipes, conduits, and cables. This process can be air-driven and are used in numerous industries, such as utilities and telecommunications, at sites in dense, urban areas and/or where traditional vertical excavations are too dangerous (e.g., under bodies of water).

Compressors in the DrillAir line can power large-diameter and/or long-run HDD processes with high throughput. The power of these units maximizes the efficiency of drilling operations, lowering project overhead and decreasing downtime.

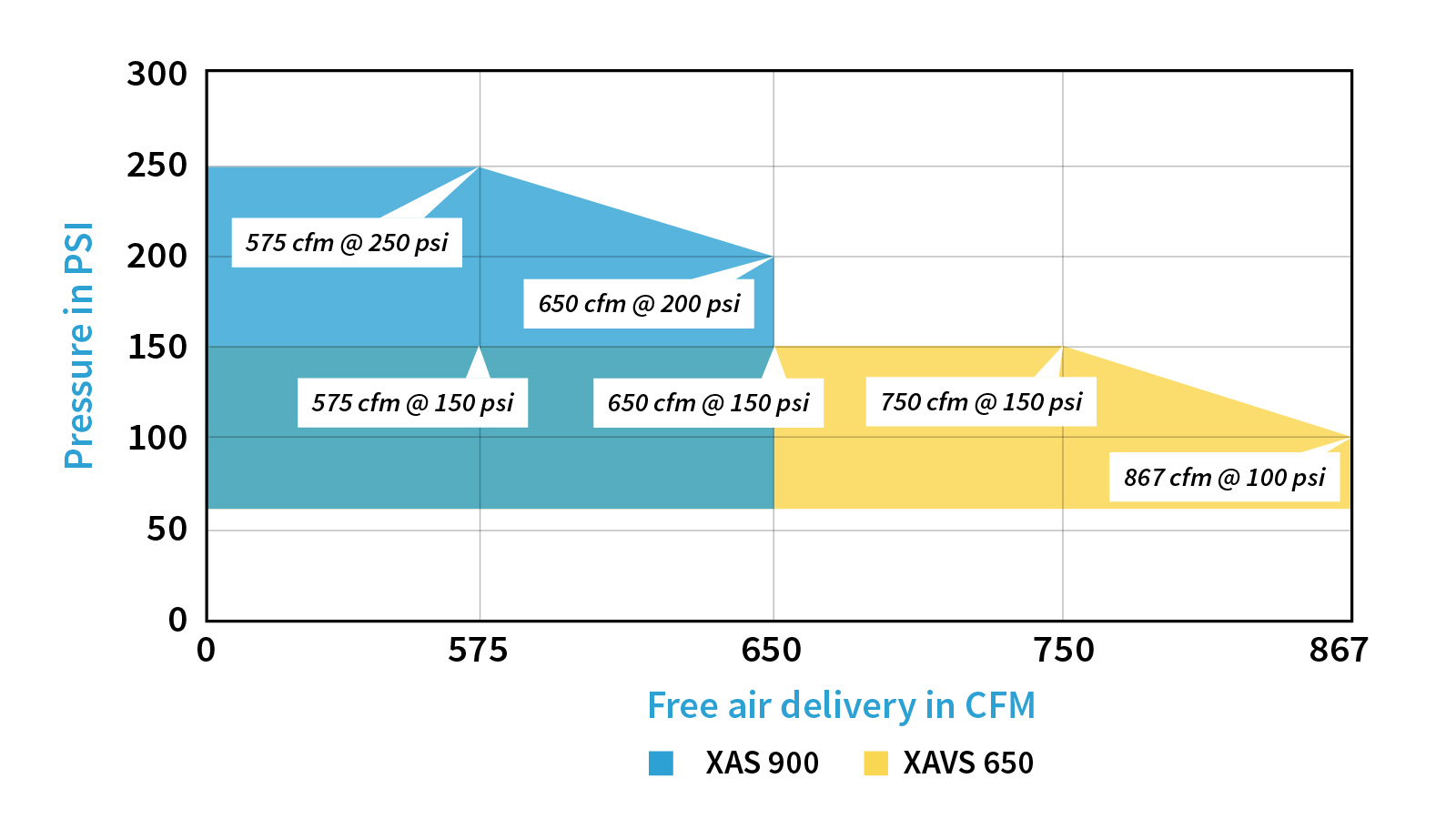

The DrillAir range provides one of the highest air volumes at one of the highest air pressures available in the portable compressor industry. This also makes these new compressors one of the most energy efficient by having a very low specific fuel consumption for the air delivered.

Dynamic Flow Boost ® increases flow from 34.8 to 39m³/min (650l/s) when flushing and during drill stem refill. It means faster flushing, faster stem refill and a shorter time to finish a well.

High penetration rate with 35 bar pressure and 34.8m³/min (580l/s) flow means more meters drilled every day.

The units were tested both in lab and field conditions to ensure optimal performance. It’s designed to withstand the toughest working conditions. We have a mobile compressor for any indoor or outdoor application. On top of peace of mind, you'll also gain low noise levels, small footprint, fuel efficiency or zero diesel emissions, high resale value, easy to use and intuitive controllers... and much more.

The 400 cfm range extends the compressor oil service interval to 1000 hours or once every two years. Reduced service intervention and longer life of consumables reduces total cost of operation and increases availability.