Why use our air compressors in your brewery?

Certified clean air

We have set the standard concerning uncontaminated air. Being the first compressor manufacturer to be ISO 22000 certified and the first to have been certified by a third party on ISO 8573-1 (2010) Class 0 clean air.

This gives breweries peace of mind that the air is as pure as possible. Highly trained employees manufacture compressors in a safe and controlled environment.

Solutions for every step of the brewing process

Doesn’t matter if you are a large brewery, microbrewery or a craft brewery, our compressors offer solutions for every single size, because compressed air is used in nearly every step of any brewery’s production process. From fermentation and aeration to bottling and carbonating, we can tailor our products specifically to the brewery’s needs depending on their energy, size and noise requirements.

Optimal cost of total ownership

Being the most reliable machine on the market comes with additional benefits. Having an oil-free air compressor means you do not have to replace expensive filters, there are no extra energy costs for pressure loss due to these filters. This brings down maintenance costs.

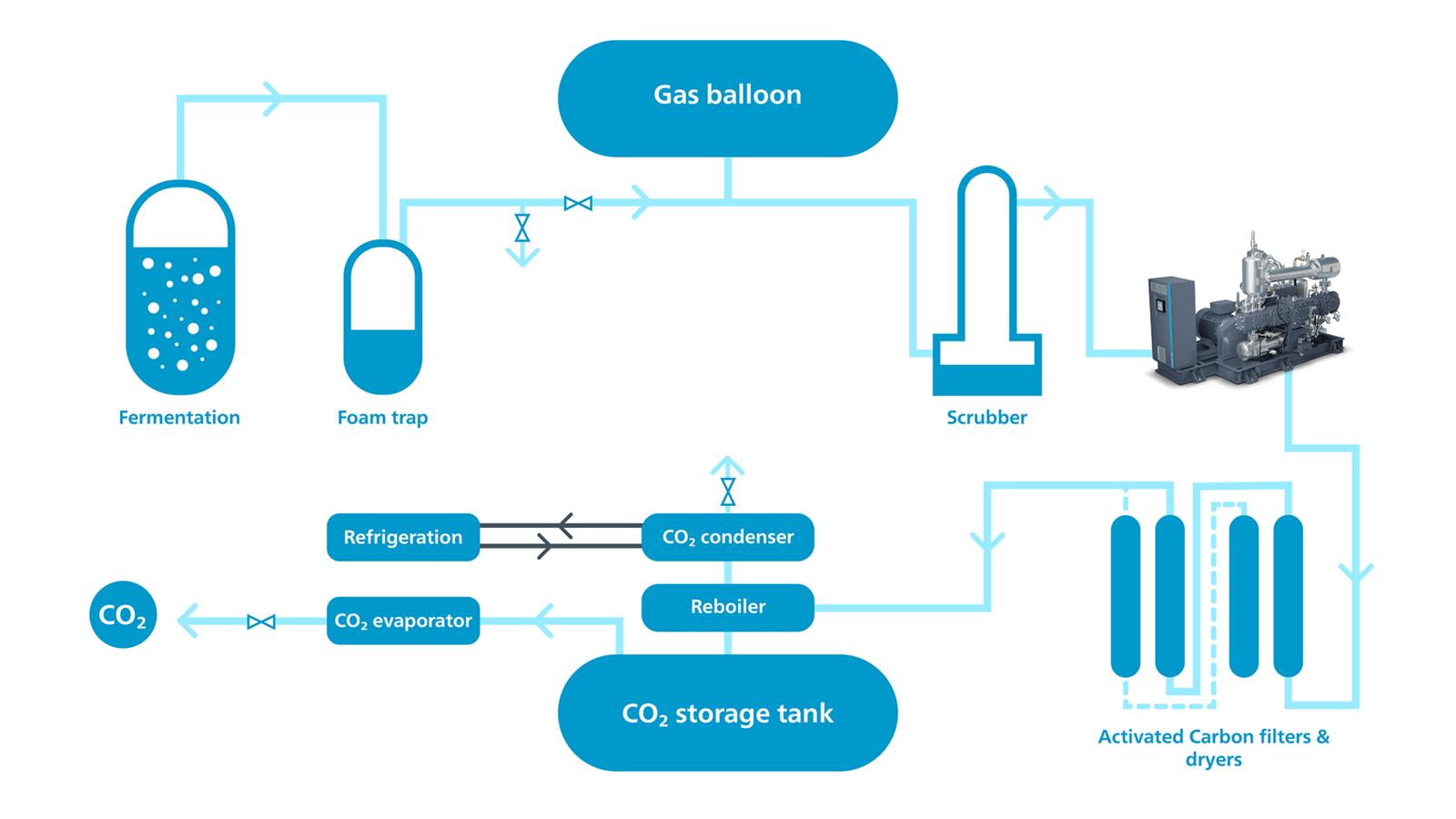

Additionally, it is possible to recover the CO2 that is created during the fermentation process for commercial ends or self-use. Finally, thanks to our global service network that contains more than 180 countries downtimes are solved in no-time, no matter where you are or at what time.

Compressed air applications in the brewing industry

Oil-free compressed air is used for cleaning bottles and packaging prior to the filling.

If the air is contaminated it can alter the flavor, odor and foam besides being a health hazard.

Oil-free compressed air is used for cleaning bottles and packaging prior to the filling.

If the air is contaminated it can alter the flavor, odor and foam besides being a health hazard.

Compressed air is used to control the valves and actuators in automated lines for packaging, labelling and more.

Oil-free air prevents automated components from jamming, thereby lowering maintenance costs.

Compressed air is used to control the valves and actuators in automated lines for packaging, labelling and more.

Oil-free air prevents automated components from jamming, thereby lowering maintenance costs.

Compressed air supplies oxygen to bacteria during the fermentation process (aeration). This converts carbon hydrates to alcohol using micro-organisms.

Important during the process is delivering the exact amount of compressed air and maintaining the correct oxygen level in order to determine the quality of the yeast.

Compressed air supplies oxygen to bacteria during the fermentation process (aeration). This converts carbon hydrates to alcohol using micro-organisms.

Important during the process is delivering the exact amount of compressed air and maintaining the correct oxygen level in order to determine the quality of the yeast.

See how our equipment is used by our brewery customers

Birra Peroni brews Class 0 beer

The world of compressed air will no longer be the same thanks to the new oil-free ZR air compressor, tested in Italy by Birra Peroni.

Barranco Beer Company brews class 0 beer

Barranco Beer Company in Peru uses oil-free air compressors provided by Atlas Copco to produce high quality class 0 beer.

Olde Mecklenburg Brewery uses oil-free air in brewing process

The Olde Mecklenburg Brewery in Charlotte, North Carolina (USA) uses oil free air compressors from Atlas Copco in their brewing processes to guarantee that their air is clean, their nitrogen is pure and their beer is always uncompromised.

Ebook: Compressed air and nitrogen for microbreweries

In this microbrewery ebook, read all about:

- the process of beer brewing

- the role of compressed air in beer brewing

- the role of Nitrogen in beer brewing

- the key compressed air and nitrogen requirements in microbreweries

- the design of a compressed air and nitrogen system

- the importance of monitoring and maintenance