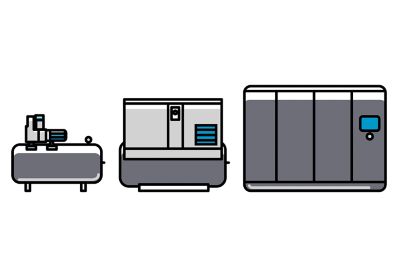

When comparing piston and rotary screw compressors, it's important to understand their operational differences and how these relate to their suitability for specific tasks. Piston compressors, also known as reciprocating compressors, are typically used for applications that require short, intense bursts of air. In contrast, rotary screw compressors are designed for applications that need a steady flow of air over extended periods.

Operational differences

Piston compressors work by drawing air into a cylinder and compressing it with a reciprocating piston. They are generally best for lower volume air needs and have a duty cycle of about 60-70%, meaning they need to shut down periodically to prevent overheating.

Rotary screw compressors, on the other hand, use two interlocking rotors to compress air and are fluid cooled, allowing for 100% duty cycle and continuous operation without the risk of overheating.

Energy efficiency

Rotary screw compressors are typically more energy-efficient than piston compressors, delivering more air per unit of input energy. For example, piston compressors generally deliver 3-4 cubic feet per minute (cfm) per horsepower (hp), while rotary screw compressors deliver 4-5 cfm per hp. This efficiency is particularly beneficial where electricity costs are high.

Air quality

The quality of compressed air is another consideration. Piston compressors operate at higher internal temperatures, which can lead to more moisture in the compressed air. This may require additional drying and cleaning components. Rotary screw compressors run at lower temperatures and often come with built-in aftercoolers to reduce the air temperature, resulting in better air quality.

Maintenance and durability

Rotary screw compressors have fewer moving parts than piston compressors, which translates to less wear and tear and lower maintenance requirements. While piston compressors are simpler in design and may be easier to maintain, they typically require more frequent service due to more moving parts.

Noise and space requirements

Rotary screw compressors operate more quietly and require less space compared to piston compressors, making them suitable for closer proximity to workspaces.

Total Cost of Ownership

The initial cost of a rotary screw compressor may be higher, but the total cost of ownership can be lower due to its increased efficiency and lower maintenance costs over time. This includes the purchase price, energy consumption, maintenance and downtime costs.

Operating costs and energy efficiency

Rotary screw compressors generally have lower operating costs and are more energy-efficient in the long run, especially for continuous use scenarios. However, piston compressors might offer savings for smaller or less frequent applications.

Atlas Copco's GA series with VSD technology is recommended for its energy efficiency. The GA 5-37 VSDˢ model, in particular, can achieve significant energy savings and has a design that minimizes energy consumption.