Operational factors of different water cooled compressors

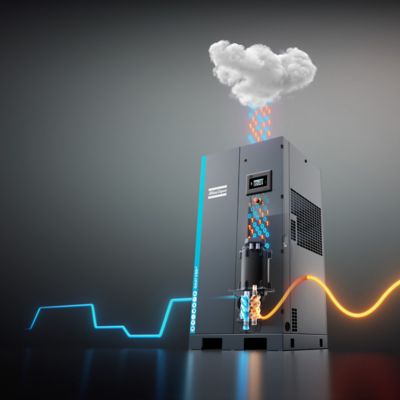

Like with computers, compressors need adequate cooling for consistent operations. To achieve this, you'll choose between air cooled and water cooled compressors.

If you pick the latter, it's important to understand the three different water-cooling methods. Let us take a look at these options and which one is worth considering for your compressed air system.

Three types of water cooled compressors

Water cooled compressors require little demand from your facility's ventilation system. This is because cooling water removes approximately 90% of the heat energy created by the electric motor.

To be effective, water cooled compressors use one of three main principles:

● Open systems without circulating water (connected to an external water supply).

● Open systems with circulating water (cooling tower).

● Closed systems with circulating water (including an external heat exchanger/ radiator).

Open system without circulating water

An open system without circulating water requires an external source. This includes municipal water mains, lakes, streams, or well water. After passing through the compressor, this water is discharged.

When using this method, the system needs a thermostat control to maintain desired air temperature and govern water consumption. Generally, an open system is easy and inexpensive to install. However, it's costly to run, especially if the cooling water comes from water mains.

Water from a lake or stream is typically free, but needs filtration and purification to limit the risk of clogging the cooling system. Furthermore, water rich in lime may result in boiler scale forming inside the coolers - causing impaired cooling. The same concerns apply to salt water, which may be used if the system is designed properly and dimensioned accordingly.

Open system with circulating water

In an open system with circulating water, cooling water from the compressor is re-cooled in an open cooling tower. This process involves air blown through a chamber. As a result, part of the water evaporates. The remaining water is cooled to 2˚C below the ambient temperature (depending on external factors including humidity).

Open systems with circulating water are primarily used when the availability of an external water supply is limited. The disadvantage of this system is that the water gradually becomes contaminated by surrounding air. In addition, the system must be continuously filled up using external water due to evaporation.

Another downside is that dissolvable salts are deposited on the compressor's hot metal surfaces, reducing the cooling tower's heat transfer capacity. Also, the water needs regular analysis and chemical treatment to avoid algae growth.

During winter, when the compressor is not operating, it's important to drain or heat the water to prevent freezing.

Closed system with circulating water

In a closed cooling system, water continuously circulates between the compressor and an external heat exchanger. This heat exchanger is, in turn, cooled by either an external water circuit or surrounding air.

When a water circuit cools water, a flat plate heat exchanger is used. With surrounding air, a cooling matrix consisting of pipes and cooling fins is used. The surrounding air is forced to circulate through the pipes and fins by means of one or more fans. This method is suitable if the availability of cooling water is limited.

The cooling capacity of open or closed circuits is about the same. That is, the compressor water becomes cooled to 5 °C above the coolant temperature. If surrounding air cools the water, you'll need antifreeze (e.g. glycol).

The closed cooling water system is filled with pure, softened water. With glycol, the compressor system's water flow must be recalculated. The type and concentration of glycol affects the water's thermal capacity and viscosity.

It is also important to thoroughly clean the system before it's filled for the first time. A correctly implemented closed water system requires minimal supervision and low maintenance costs.

For installations where the available cooling water is potentially corrosive, the cooler should be designed in a corrosion-resistant material such as Incoloy.

Air-cooled compressors

As referenced in the introduction, most modern compressor packages are also available in an air-cooled version. This setup involves forced ventilation inside the air compressor.

As a result, higher energy is consumed due to constantly running a fan. However, air-cooled compressors tend to be cleaner with fewer contaminants running through your equipment.

Choosing the right equipment

We hope this article helps you understand which type of air compressor cooling method is most appropriate for your setup, application, and needs. If you require additional insight, our team is happy to help. Please feel free to get in touch today to receive custom tailored advice.

Avec l'électricité, l'eau et le gaz, l'air comprimé fait tourner le monde. Nous ne le voyons peut-être pas toujours, mais l'air comprimé est partout autour de nous. En raison de la diversité de ses utilisations (et de la demande), les compresseurs sont désormais disponibles dans tous les types et toutes les tailles. Dans ce guide, nous décrivons le rôle des compresseurs, les raisons pour lesquelles vous en avez besoin et les types d'options qui s'offrent à vous.

Besoin d'aide supplémentaire ? Cliquez sur le bouton ci-dessous et l'un de nos experts vous contactera sous peu.

Related articles

30 juin, 2022

Découvrons comment est récupérée l'énergie de la chaleur résiduelle dans les circuits d'air comprimé refroidis par eau ou refroidis par air. Nous examinerons le potentiel de récupération, ainsi que les différentes méthodes de récupération d'énergie.

31 mai, 2022

L'installation d'un compresseur est plus simple qu'avant. Mais il y a cependant quelques éléments à garder à l'esprit, le plus important étant le lieu où installer le compresseur et la manière d'organiser l'espace autour de ce dernier. Pour en savoir plus, cliquez ici.

25 avril, 2022

Un certain nombre de décisions doivent être prises lors du dimensionnement d'une installation d'air comprimé afin qu'elle s'adapte à différents besoins, qu'elle offre un maximum d'économies d'exploitation et qu'elle soit prête pour une future expansion. Pour en savoir plus, consultez cet article.