Jak vám můžeme pomoci?

Vyhledat užitečné informace

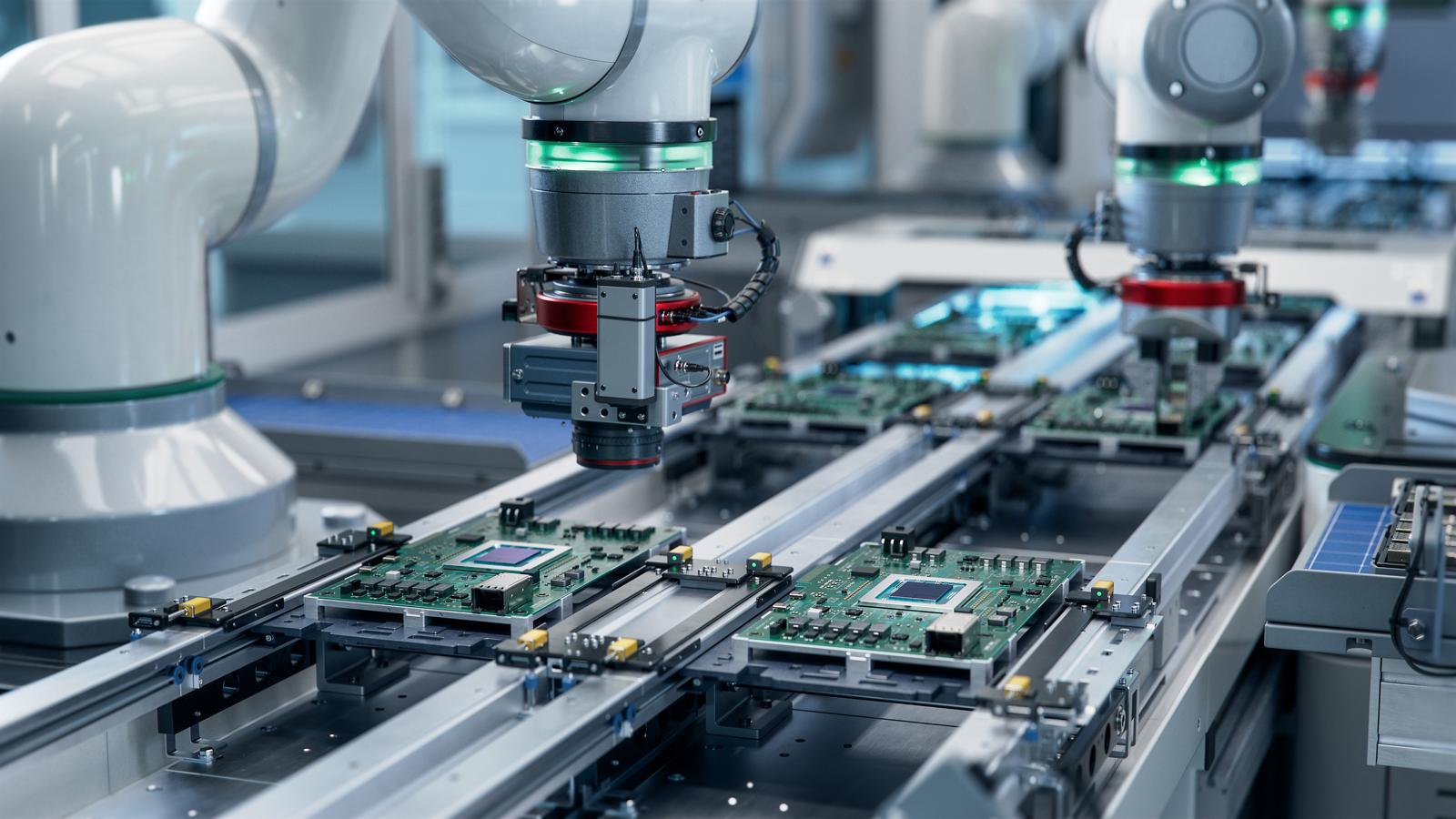

Prozkoumejte naše servisní řešení v České republice

Pro kterou aplikaci potřebujete naši podporu?

Často kladené dotazy

Co je preventivní údržba?

Preventivní údržba je jakákoli preventivní činnost prováděná na nářadí nebo montážním zařízení, která obecně zahrnuje výměnu opotřebovaných dílů nebo mazání – například pomocí soupravy pro údržbu. Po preventivní údržbě je nutné provést test. Pokud pracujeme s montážním nářadím, je nutná také kalibrace.

Co je Středisko správy nástrojů?

Středisko správy nástrojů (TMC neboli Tool Management Center) je součástí naší smlouvy o úrovni služeb ToolCover Uptime. Jedná se o jedinečný servisní model společnosti Atlas Copco, kdy se naši zaměstnanci pohybují v zařízeních zákazníka, v rámci pevně stanovených plánů a v určeném prostoru. V tomto prostoru jsou vybaveni všemi potřebnými nástroji pro opravy nebo údržbu nářadí společnosti Atlas Copco nebo jiných značek utahovacího nářadí, nástrojů pro demontáž, rázového nářadí, zdvihacích zařízení atd., a také pro správu instalované základny.

Ve Středisku správy nástrojů společnosti Atlas Copco provádějí naši certifikovaní servisní technici a inženýři konkrétní preventivní údržbu a kalibrace. Přebírají odpovědnost za údržbu zaměřenou na spolehlivost (RCM neboli Reliability Centered Maintenance), podporu linky, nastavení a správu dokumentů ISO. Naším cílem je zkrátit časové plány (Turn Around Times), aby se zvýšila produktivita zákazníků.

Jak často bychom měli kalibrovat nářadí?

Podle mezinárodních směrnic od asociace ILAC (International Laboratory Accreditation Cooperation) závisí kalibrační interval na několika faktorech, včetně četnosti používání, požadované přesnosti a interních požadavků na kvalitu ve vaší společnosti. Systém řízení kvality zákazníka by měl definovat interval kalibrace, jako je například ISO9001. Pokud však neexistují žádné požadavky na kvalitu nebo regulaci, doporučujeme provádět kalibraci nářadí a měřicích zařízení každých 12 měsíců. V mnoha aplikacích, kde má bezpečnost kriticky důležitý význam, nebo ve zdravotnických aplikacích vyžadují směrnice interval 3 až 6 měsíců.

Kalibrace je zahrnuta v našich programech preventivní údržby, konkrétně v programu ToolCover.

Jak co nejrychleji opravit naše zařízení pro dávkování, nýtování a upevňování?

Vyzkoušejte naše středisko oprav! Zde nabízíme vysoce kvalitní opravy s originálními náhradními díly. Vyberte si strategii oprav, která vám nejlépe vyhovuje, snižte celkové náklady na vlastnictví a mějte svůj rozpočet pod kontrolou.

Přečtěte si více na našem blogu

Vyhledání nejbližšího servisního střediska

nalezená umístění