The PAC H43C KD 74HP T4F for high-pressure applications, have been designed to reduce downtime and prolong lifespan, saving operational costs.

This centrifugal pump can handle liquids containing solids of up to 3" in size. This makes it particularly well suited to industrial applications, such as water transfer in the oil and gas sector, quarrying and surface mining, construction, and municipal applications.

Even with suction heights of several feet the machine rapidly evacuates the air from the suction pipe and starts to pump. Additionally, thanks to the enclosed impeller, the PAC range is also suitable for pumping liquids with solids in suspension with best possible efficiency.

| Pump | |

|---|---|

| Model | PAC H43C |

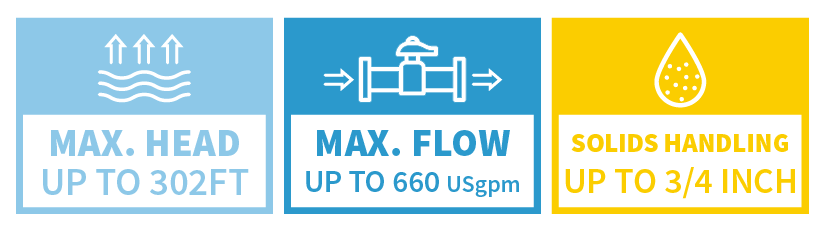

| Qmax | 660 USgpm |

| Hmax | 302 ft |

| Q max eff. | 570 USgpm |

| Eff. max | 62 % |

| Suction port | 4" Flange - ANSI class 150 |

| Delivery port | 3" Flange - ANSI class 150 |

| Impeller type | Semi-open, 4 vane |

| Impeller diameter | 12" |

| Solids handling | 3/4" |

| Material | |

| Casing | ASTM A536 80-55-06 ductile iron |

| Impeller | ASTM A536 80-55-06 ductile iron |

| Wear plate | ASTM A48 Class 20 grey iron |

| Shaft | SAF 2205 stainless steel |

| Mechanical Seal faces | Silicon carbide Vs Silicon carbide |

| Flushing | Yes |

| Elastomers | VITON |

| Lubrication | Oil |

| Check Valve | ASTM A536 ductile iron + NBR rubber flap |

| Separator | Aluminium alloy |

| Priming System | |

| Vacuum pump | |

| Vacuum pump type | Diaphragm |

| Nominal air capacity | 29.4 cfm |

| Max vacuum | - 26.6 inHg |

| Drives | Link belt |

| Engine | |

|---|---|

| Make | Kohler |

| Model | KDI 2504TCR |

| Type | Diesel turbo common rail |

| Displacement | 151 in³ |

| No. cylinders | 4 |

| Cooling | Liquid with radiator |

| Rpm type | Variable |

| Max operating speed | 2,600 rpm |

| US emissions | EPA Tier 4F |

| Starting | Electric |

| Engine system voltage | 12 V |

| Engine Power rating | 74 HP |

| Control panel | |

| Model | PW 750 |

| Manual operation | |

| Automatic operation: start-stop with transducers or floats | |

| FleetLink Optional | |

| Arrangement | |

| Technical data | |

| Material | ASTM A36 steel |

| Coatings | Epoxy powder, average thickness of 3 MIL |

| Features | Lifting beam. Fork lift pockets. Pump access through hinged door. Protected PE fuel tank |

| Battery | Acid charge Pb-Ca maintenance free, 12V - 1,100 CCA |

| Fuel tank capacity | 60 USG |

| Fuel consumption | 3.7 US Gal/hr @2,600rpm @62% eff. |

| Dry weight | 3,215 lbs |

| Wet weight | 3,665 lbs |

| Speed | Impeller Dia. | Style | Solids Dia. | Ns | Suction | Discharge | No. Vanes |

| Various | 12" / 305 mm | Semi-open | 3.4" / 20 mm | 2,600 rpm | 4" / 100 mm | 3" / 76 mm | 4 |

-2_03.jpg)

-2_05.jpg)

-2_06.jpg)

| Efficiency The 12" impeller with 62% efficiency at B.E.P. provides best pumping result with minimal efforts |

Solids handling Closed impeller type with solids handling capability of 3/4" for trouble free operation |

Easy maintenance Hinged cover for direct access to the impeller and pump volute |

Polyethylene Fuel tank Corrosion-free PE tank provides longer lifetime and avoids tank cleaning due to oxidation |

Site dewatering is the process of taking and removing water from construction sites, quarries, mine shafts, or any other area. Extracting water from these areas is crucial to maintain a safe working environment as well as reduce any costly delays.

Due to the PAC's ability to handle pumping high volumes, this pump is able to displace not only water, but sewage, industrial waste, chemicals, and even some solid products.

Areas for site dewatering :

Bypass pumping involves maneuvering liquid (sewage, trash, water, etc.) around a damaged pipe without interrupting the flow of liquid while the repairs are underway. This process is critical for many rehab projects, as it allows for a pipe to be repaired or replaced without spillage on public or private property.

Bypass pumping uses a PAC H, which is a centrifugal pump that can handle liquids containing solids of up to 3/4". Because of this, the PAC H pump is well suited for bypassing in construction, industrial, and municipal applications.

Bypass is common in these sectors:

Water transfer refers to the moving of water from one location to another, often to support hydraulic fracturing. The PAC H is a centrifugal pump that can handle heads up to 3/4", which makes it well suited for water transfer in the oil and gas sector, quarrying and surface mining, construction, and municipal applications.

The PAC H pump's design benefits make them well suited for water transfer. These pumps are able to be used often and on jobs where pumps must run continuously.

Water transfer is most common in the oil and gas sector.