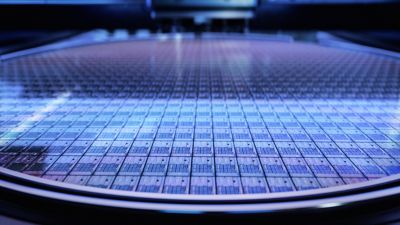

Semiconductors are the brains of many modern electronics, and as such, they need to be made without flaws. This is why the rework and maintenance of CMP polishing heads are critical. This industry calls for assembly solutions capable of providing lightweight, ergonomic tools that not only guarantee the quality of each fastener but can also guide operators through the entire rework process with clear step-by-step instructions and focuses on controlling the sequence of the assembly (position control). This is why our customers reach out to Atlas Copco.

When a major player in the semiconductor industry needed a solution to guide operators during a critical application, they reached out to our experts for help. As an avid provider of smart industrial power tools and solutions, we knew just the ensemble that would transform their assembly. Read on to discover the solutions.

Operator guidance and data collection

In the semiconductor industry, it is understood that production needs to be free of mistakes. Software solutions are one of the best resources for avoiding and preventing errors. With the right software solution at your side, operators can be guided through the entire process, enabling them to get it right the first time or catch the mistakes as they happen.

That’s where Scalable Quality Solution 3 (SQS) can help! This error-proofing software solution drives quality, process reliability, transparency, and product quality at your assembly stations. Whether at just a single station or your whole production line, SQS is ready to reduce errors by providing the user with visual operator guidance. With this feature, there is no question of the last task completed or what needs to be done next, reducing the occurrence of rework and scrap.

On the other hand, for data collection purposes, there’s ToolsNet 8. With ToolsNet 8, users can easily monitor and collect real-time data from every tightening result and torque-angle trace, making it a dependable solution. With this feature, we can relate every CMP polishing head by serial number with the results generated during the assembly process.

Guiding operators through position control technology

When the assembly must be performed in a specific sequence, it’s necessary to complement our software solutions with accessories that will allow us to guarantee operator performance. These accessories are known as position control solutions or industrial location solutions.

At Atlas Copco, we have a range of Industrial Location solutions to best fit our customers’ needs. Since the rework of CMP polishing heads is performed on a bench station, our experts knew Industrial Location Guidance (ILG) would best fit this application. This is the perfect solution to ensure consistent production quality and throughput. It can track the tool's exact location relative to the desired fastening position. In this way, ILG ensures that the correct fasteners are tightened to specification and in the proper sequence, eliminating errors at their source.

Easy programming, flexibility, and ergonomics with the right assembly tool

Lastly, our new IxB tools have been a total game-changer in terms of flexibility, ergonomics, and quality! With a 30% size and weight reduction vs. previous battery tool generations, Tensor IxB facilitates the operator to perform any task, even in small accessibility areas. Tensor IxB tools can easily change the trigger orientation and angle head. Furthermore, the integrated HMI provides clear operator feedback, including whether or not the assembly was performed correctly, ensuring production quality and reducing defects.

Why choose Atlas Copco?

When you opt for Atlas Copco to provide your assembly tools and solutions, you will also receive exceptional care and service from our team of experts. We strive for your success, regardless of the industry you belong to. That's why our experts analyze your assembly to ensure that we offer you the most suitable solutions that cater to your specific needs.

Whether you’re a member of the semiconductor industry or any other industry, Scalable Quality Solution 3, ToolsNet 8, Industrial Location Guidance, and Tensor IxB tools can make a huge impact on your assembly. To learn more about our assembly solutions, contact Atlas Copco to speak with an expert and schedule a demo today!